Precision Steel Fabrication Machinery

Built for throughput, accuracy, and uptime — from cutting and drilling to automated material handling.

Machines

High-performance systems designed for structural steel fabrication.

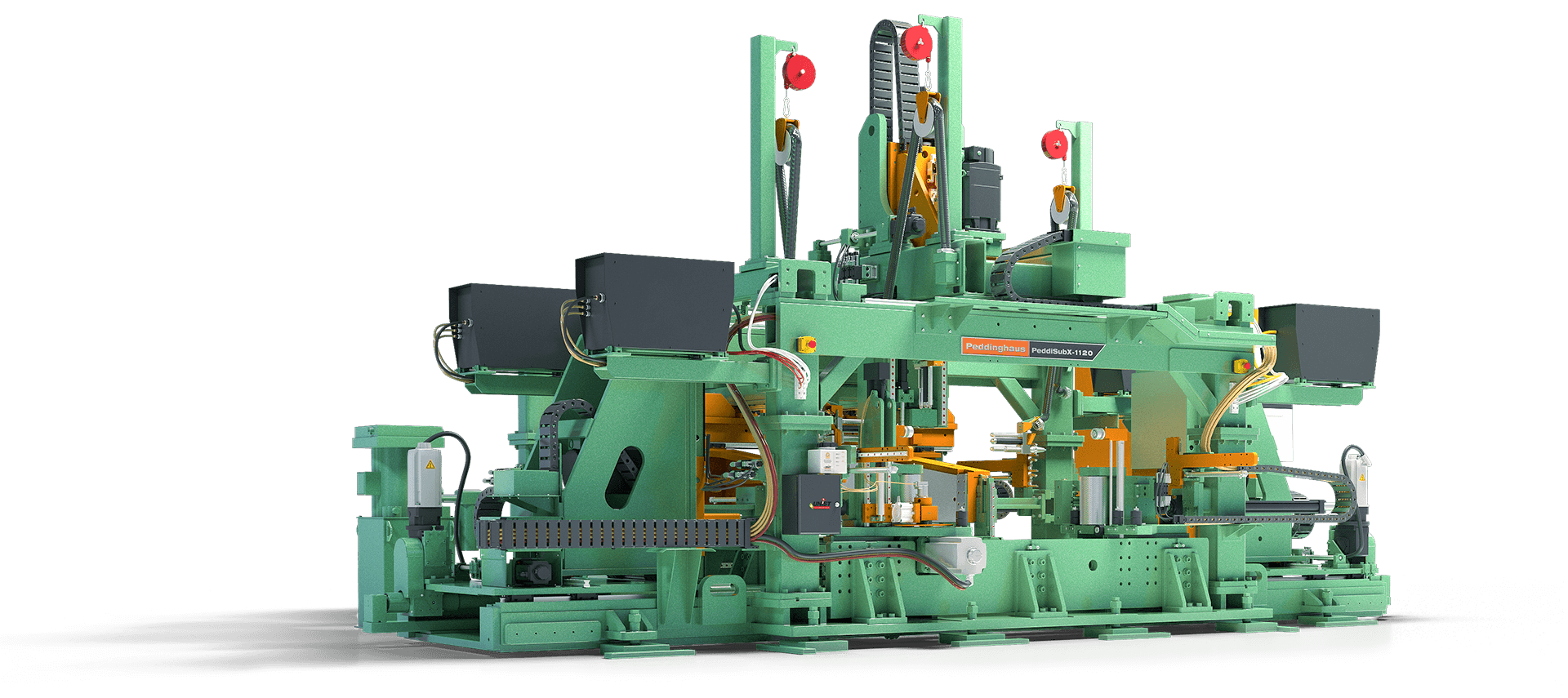

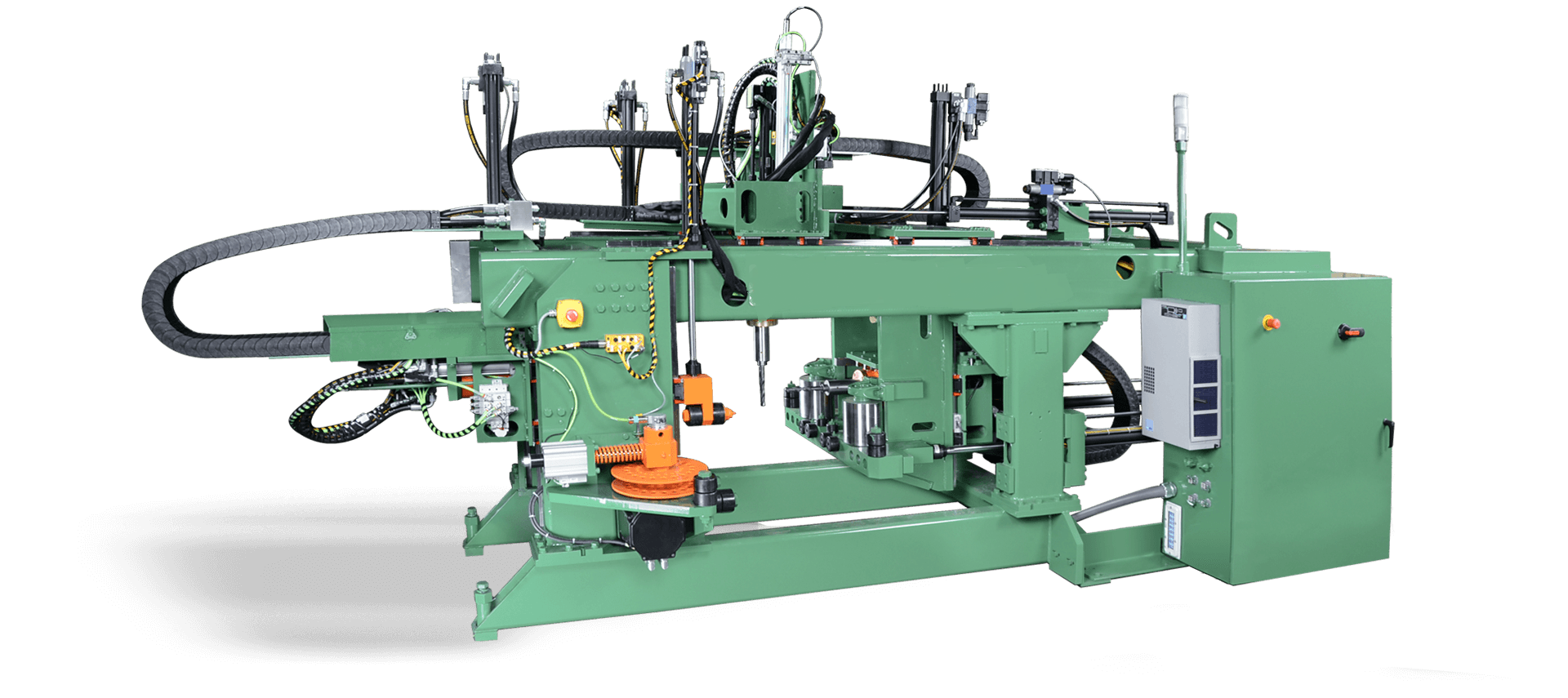

Drill Lines

CNC beam drilling lines and high-throughput fabrication systems.

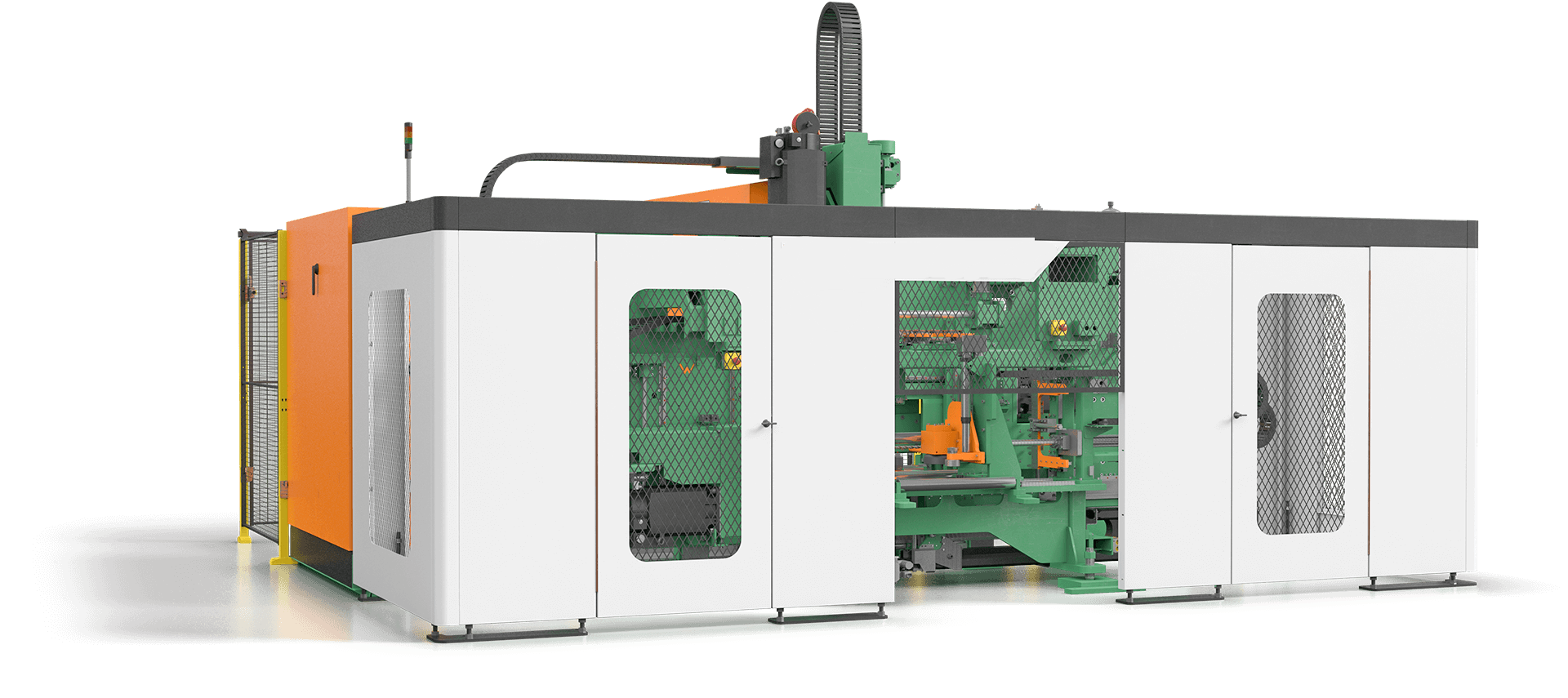

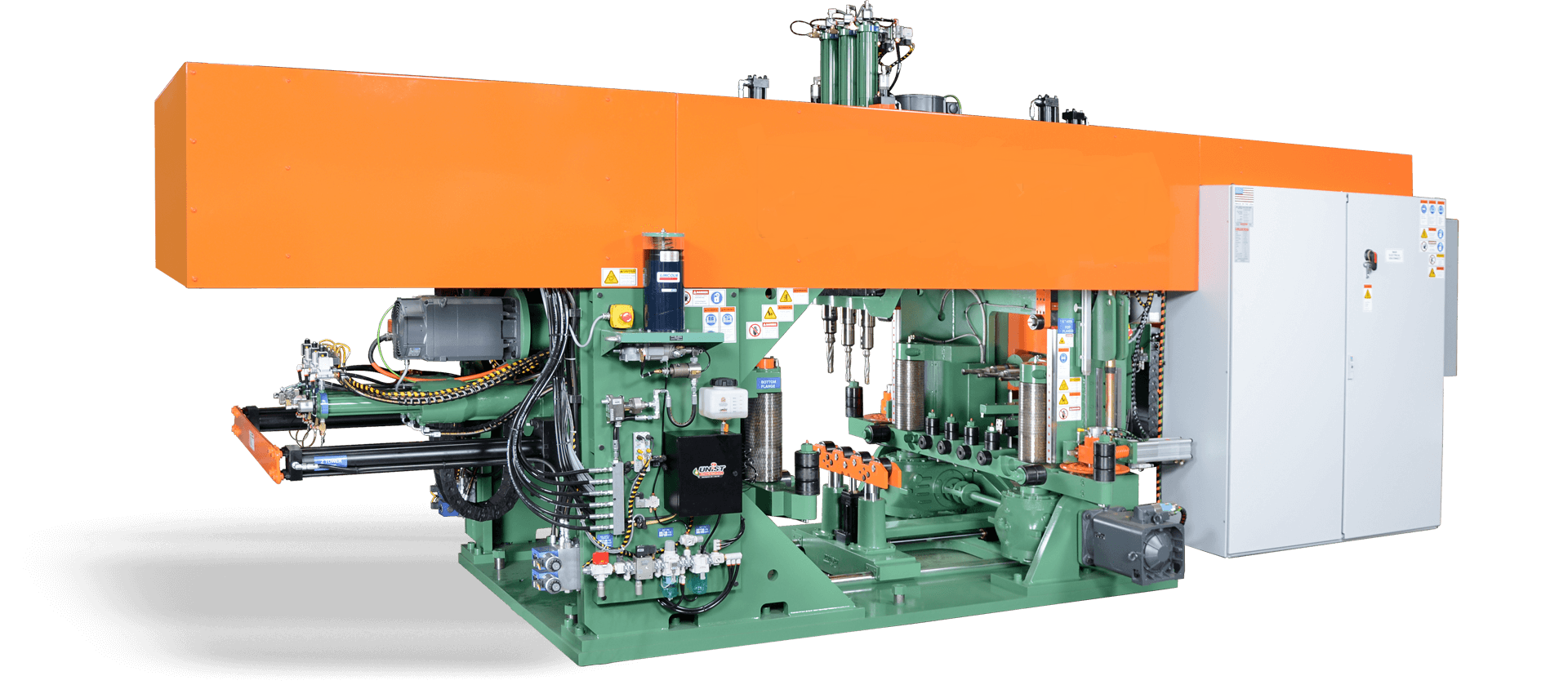

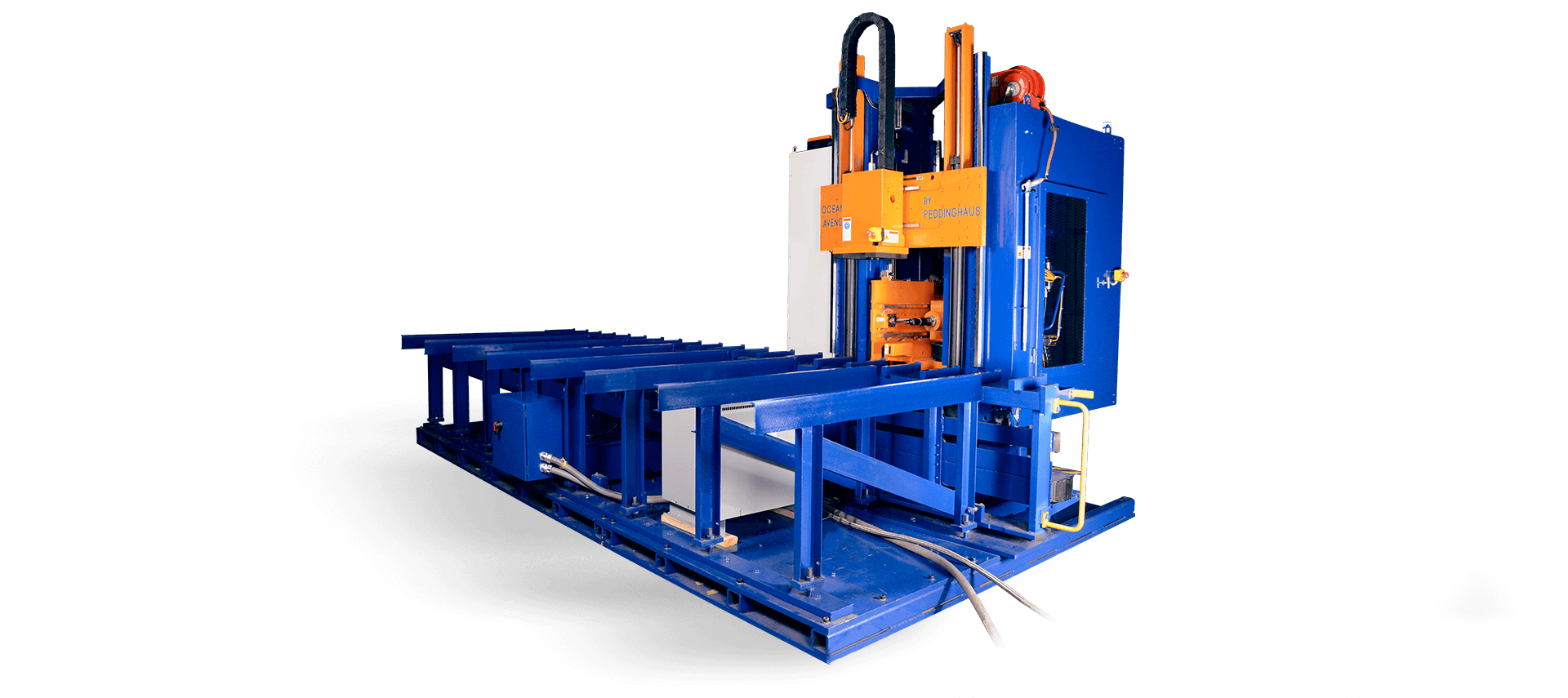

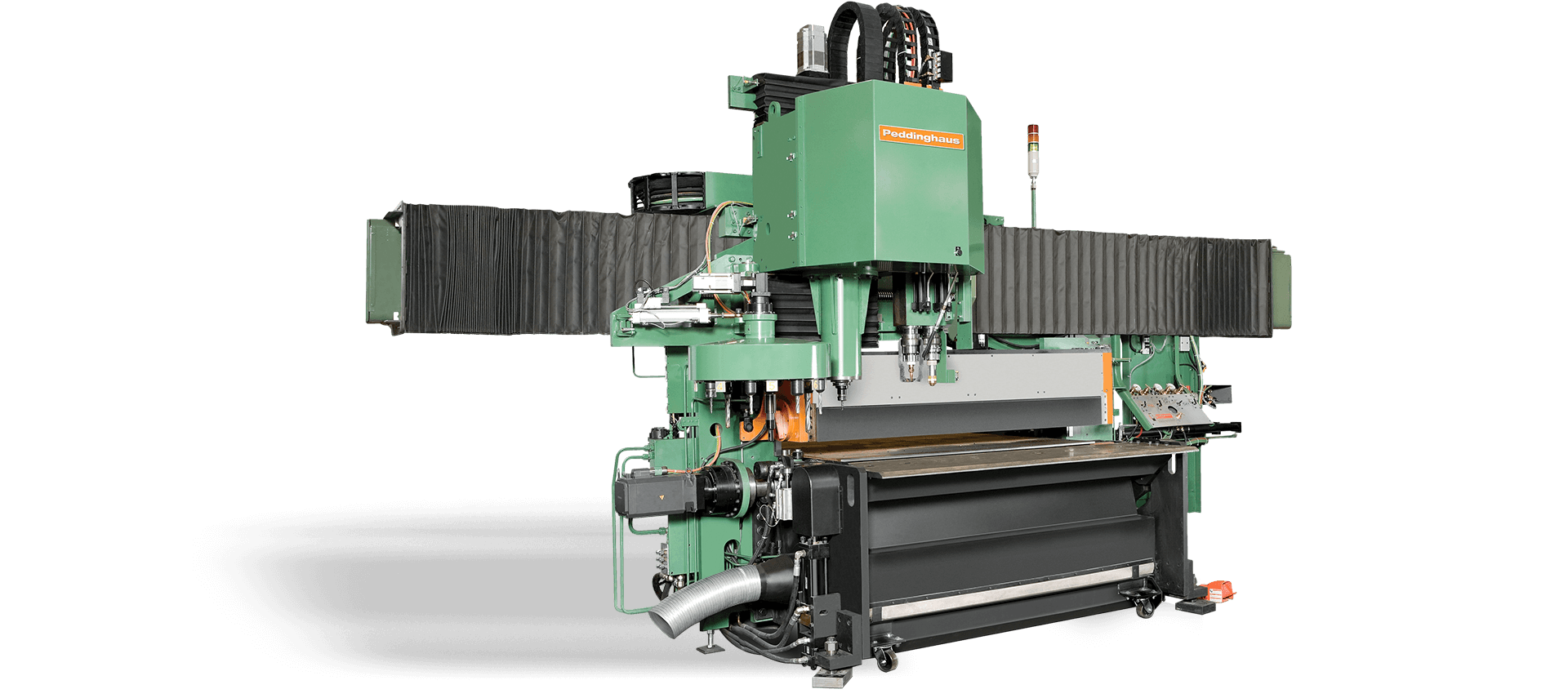

Plate Processors

High-speed plate processing, cutting, punching and scribing solutions.

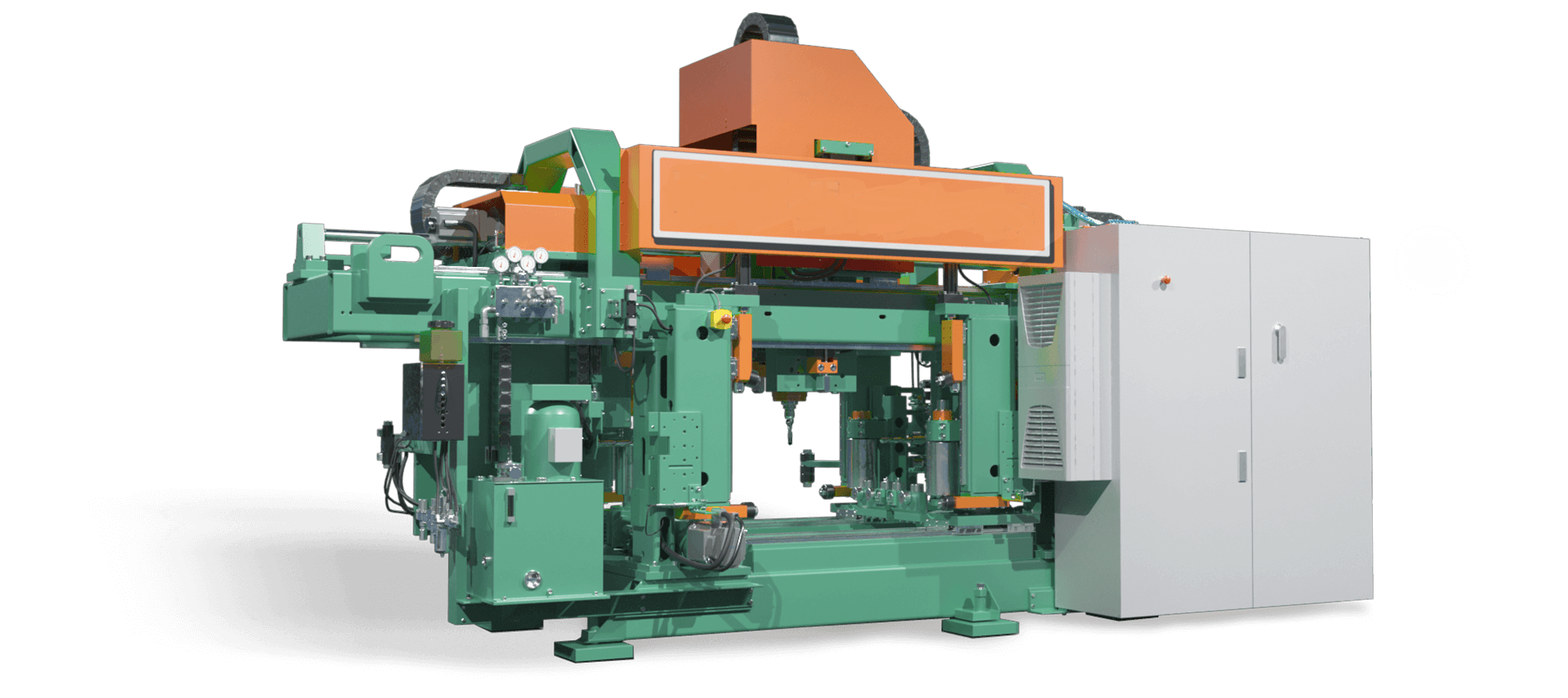

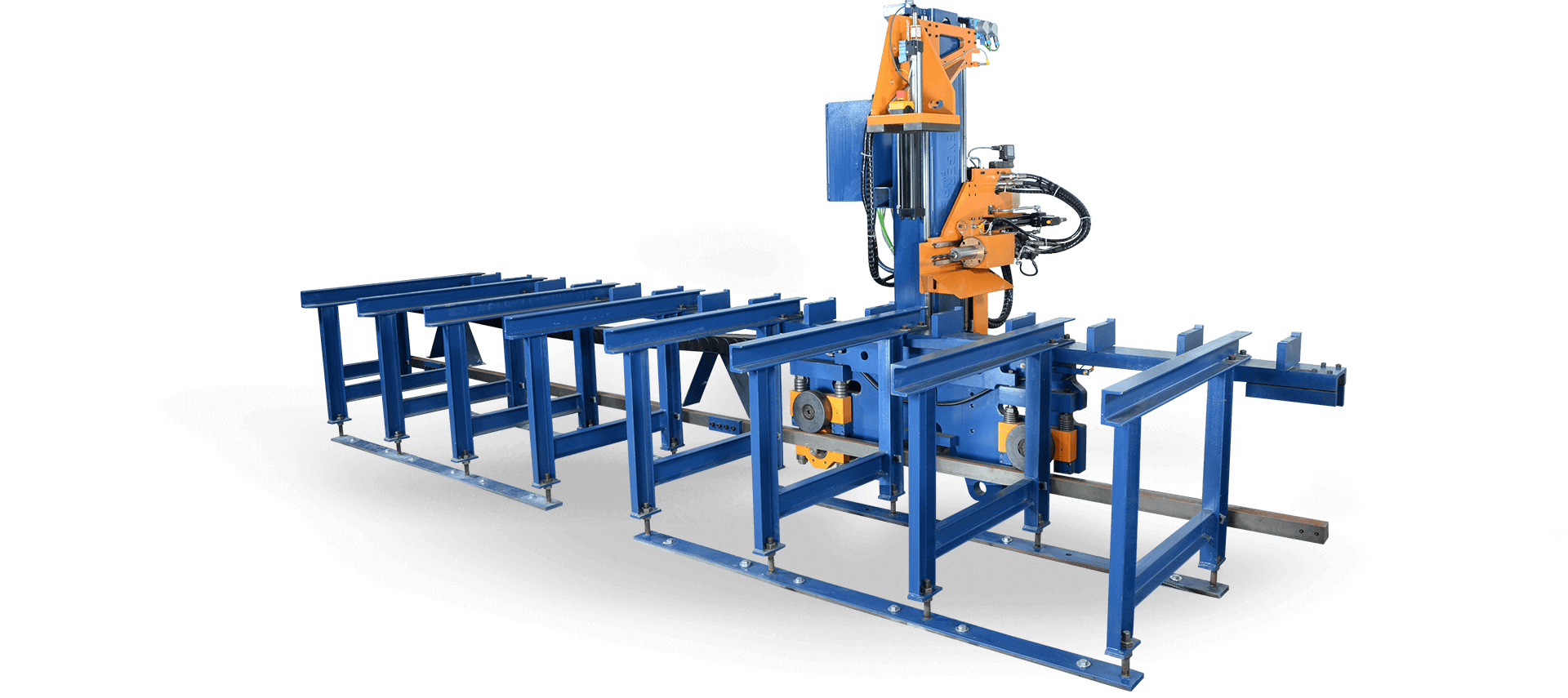

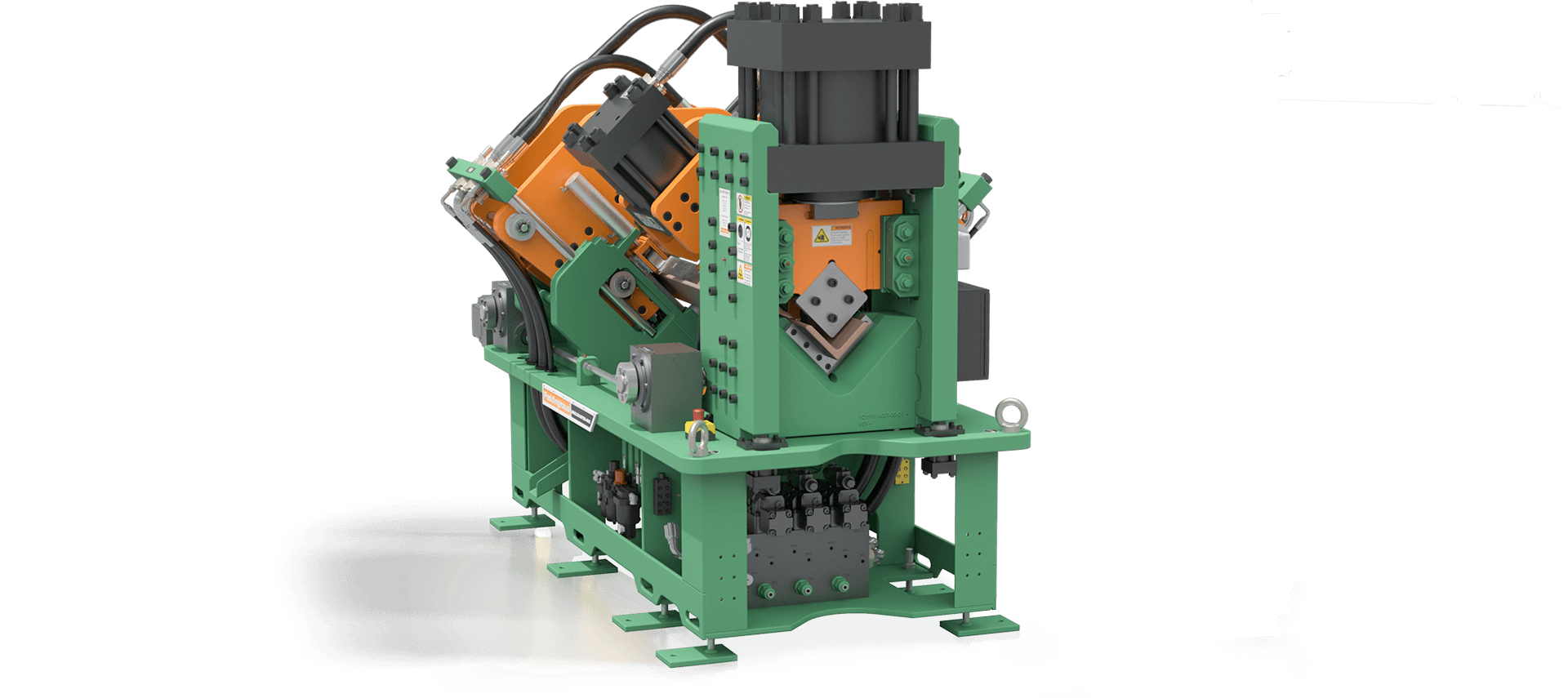

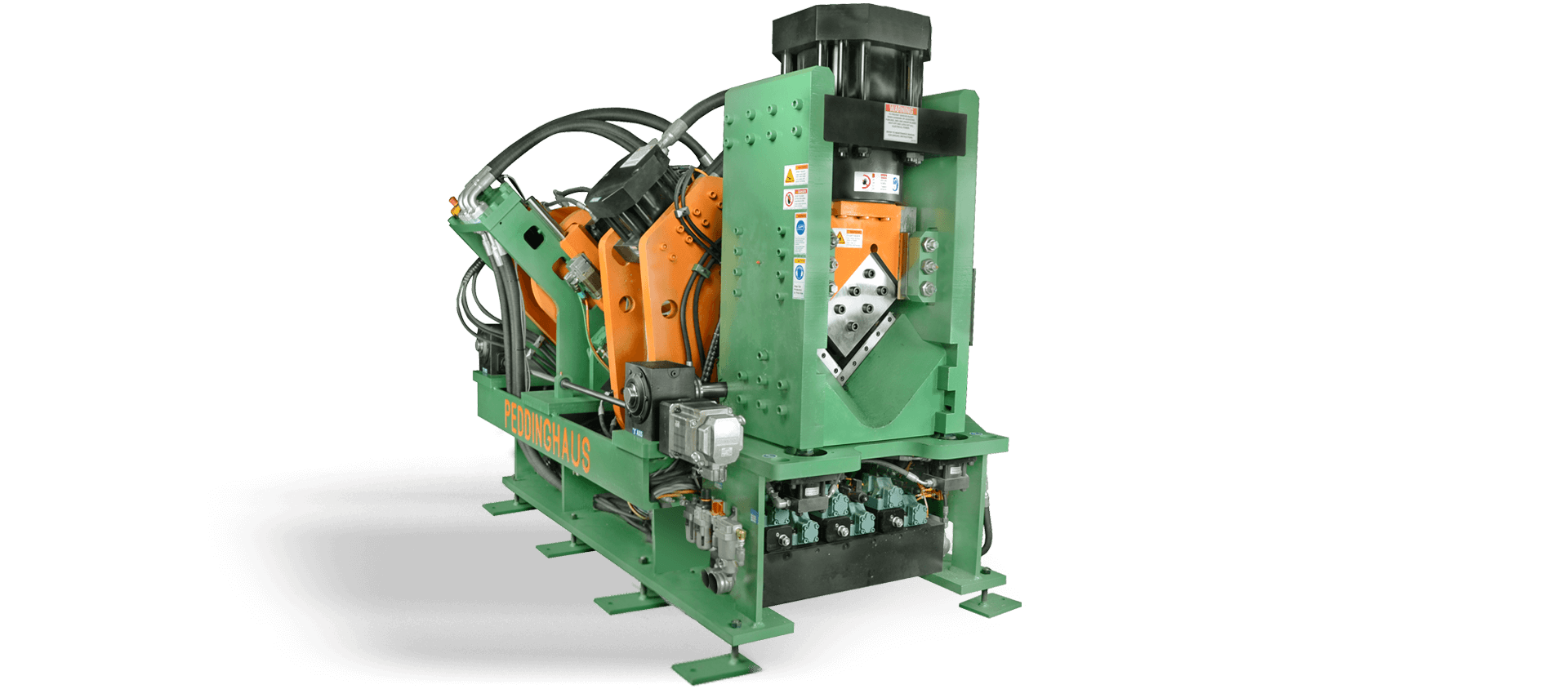

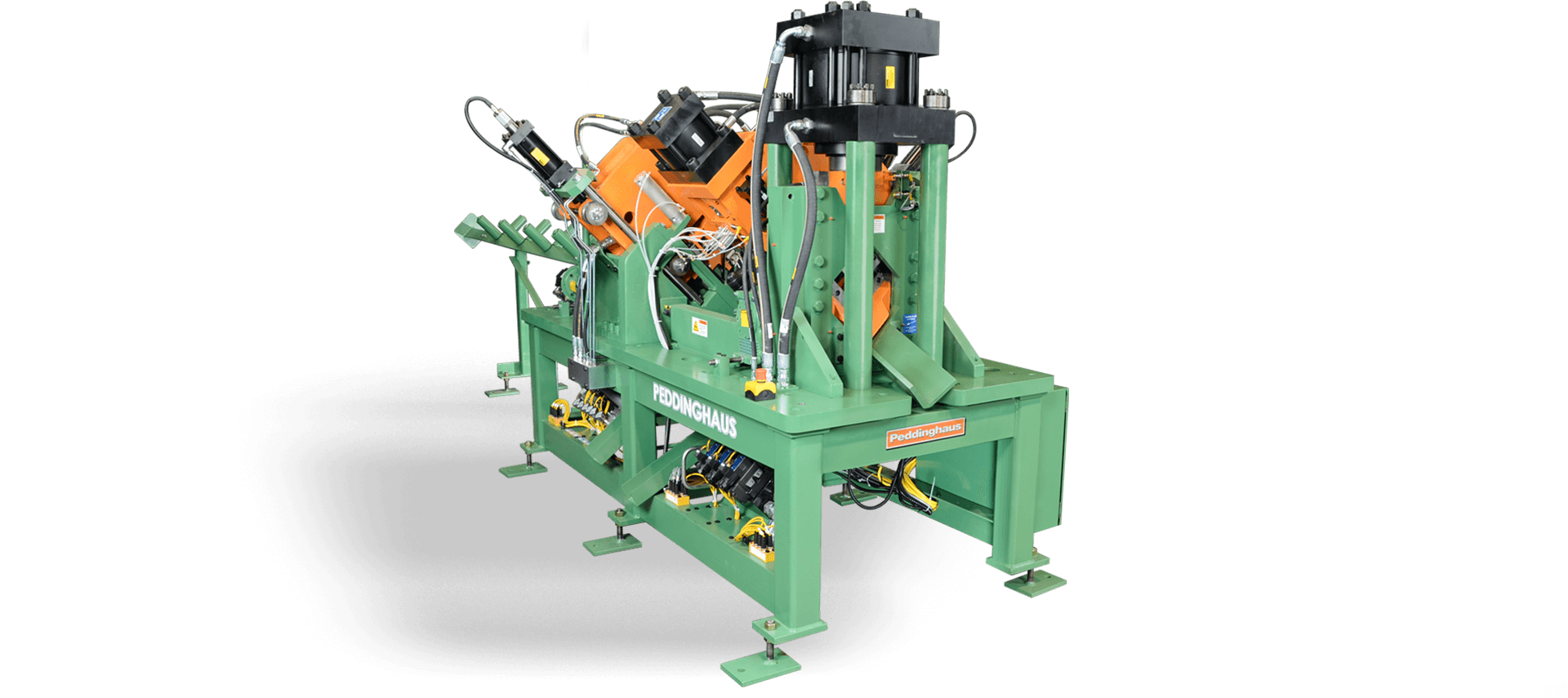

Angle Lines

Automate punching, nibbling, shearing and marking for angle and flat bar.

Drill Lines

CNC beam drilling lines and high-throughput fabrication systems.

Plate Processors

High-speed plate processing, cutting, punching and scribing solutions.

Angle Lines

Automate punching, nibbling, shearing and marking for angle and flat bar.

Software

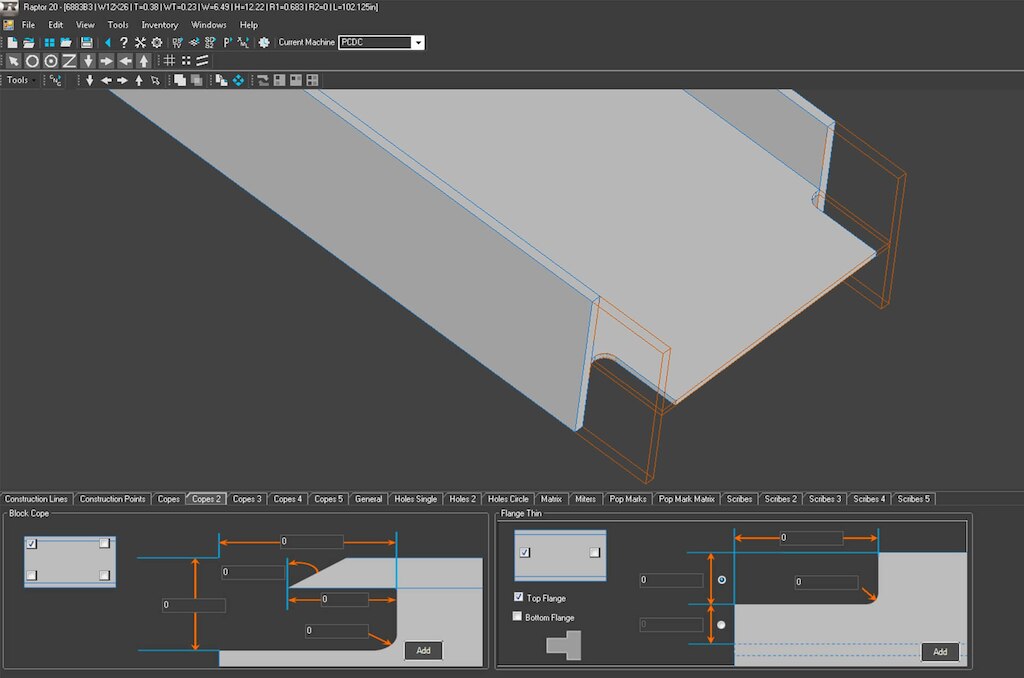

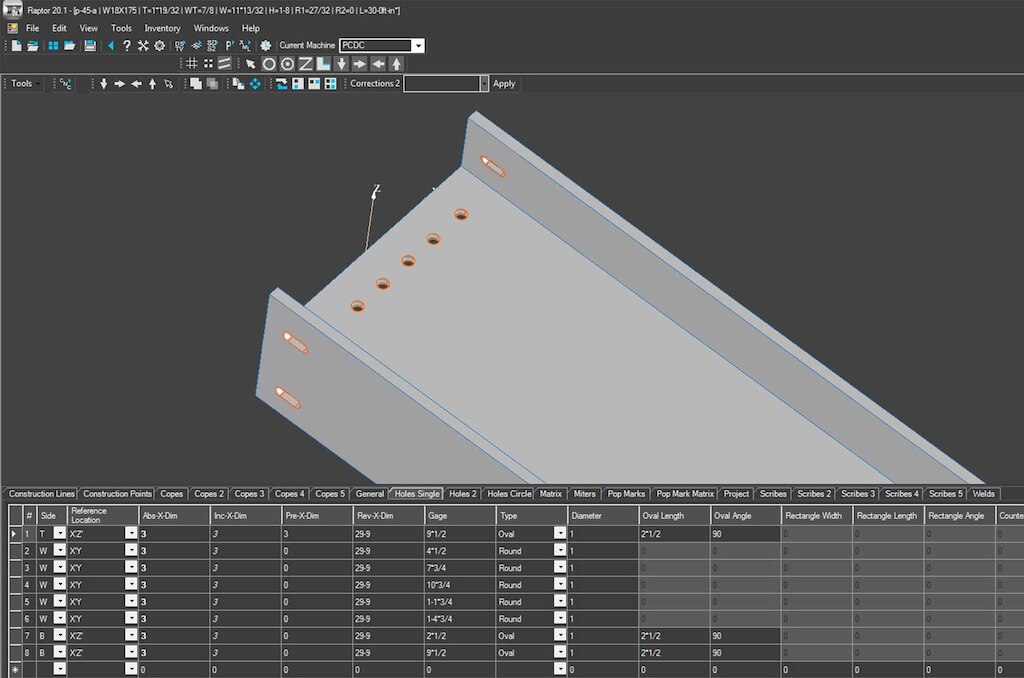

Raptor 3D CAD/CAM Software that accelerates CNC programming from design to production.

Stay Ahead of the CNC Programming Curve

Raptor 3D CAD/CAM Software from Iron Core Machinery takes CNC innovation further by enabling users to program faster and more accurately from design BIM platforms. This coupled with Iron Core Machinery CNC technology means maximum capacity for fabricators and detailers alike.

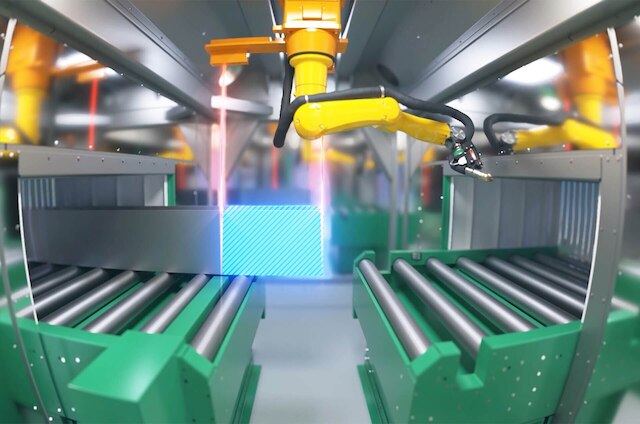

Technology

Exceeding the Needs of the Steel Industry. Through constant evolution and innovation, Iron Core Machinery remains at the leading edge of the steel industry. Working together with a common goal in mind, the Iron Core Machinery Engineering team maintains multiple individualized specialties in order to satisfy the global market of CNC steel fabrication technology. Together, their work culminates into what is widely considered the strongest, fastest and most reliable machines on the market today.

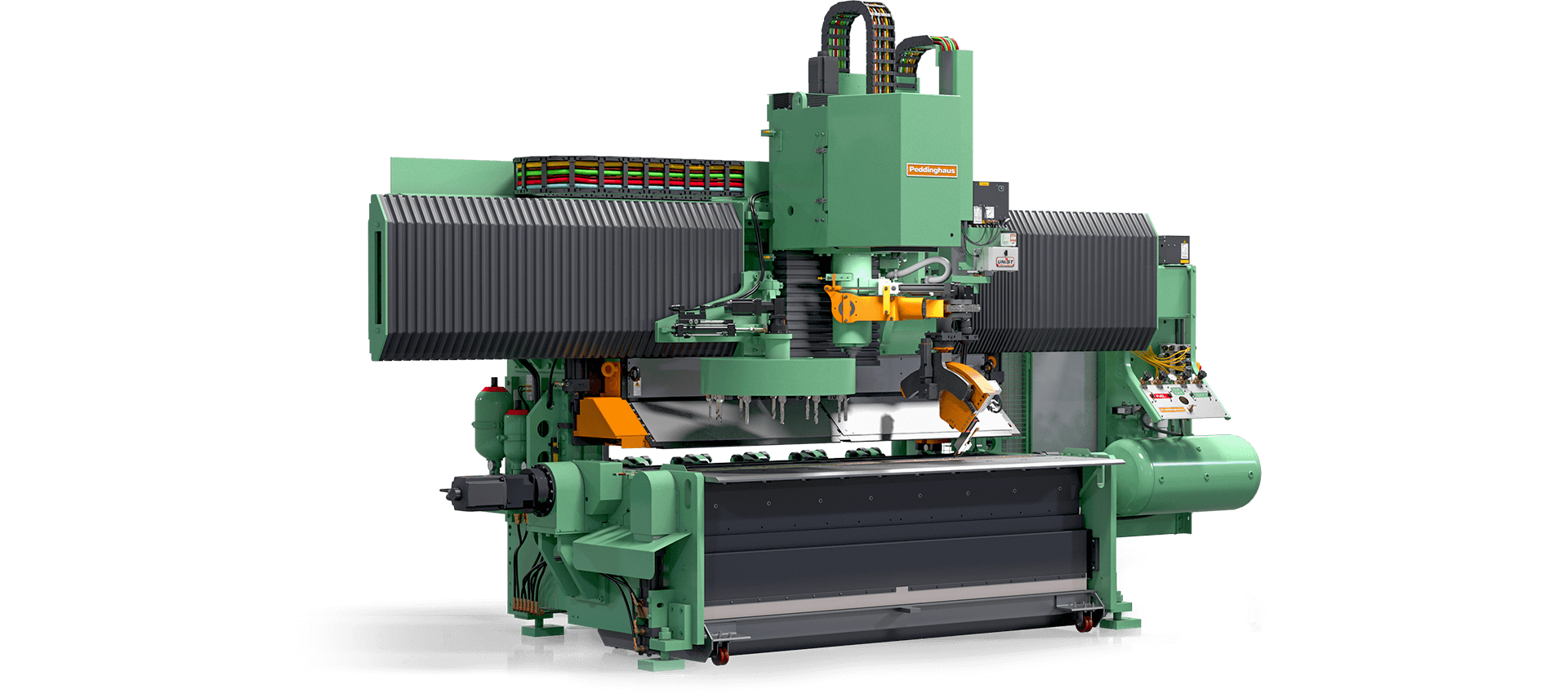

Patent Pending Plasma Marking Torch Holder

Torch assemblies that utilize a plasma marking unit operate completely independent X, Y and Z motions with ball screw feed systems.

Patented Double Torch Cutting Assembly

Unlike gantry style systems, the CNC plate processor design of Iron Core Machinery drives material to the operating area of the machine as opposed to bringing the operating area of the machine to material. This plate beveling technology is designed so that both the plasma and oxy-fuel cutting torch of the machine can utilize beveling capabilities with the application of a single cutting assembly.

Innovative Roller Feed Measurement

As accurate as measuring material can be, the Roller Feed drive and measurement system from Iron Core Machinery is designed to improve accuracy even greater than before. Steel can pass through piece after piece with no stop in production. The Roller Feed is designed to maximize contact with the material which helps eliminate errors.

Aggressive Drilling Process

Iron Core Machinery drill lines utilize Siemens electronics to achieve industry-leading hole times. The high-horsepower spindles also have high torque. This allows the carbide drills to remove more material with each rotation. A thicker, more aggressive cut on each pass will decrease drilling time and part completion time.

3D Profile Scanning System

This state-of-the-art measurement system detects positional displacement and distortions of material. The intelligent system consists of a triangulation laser scanner for measuring sections. Material scanning is executed inside the cutting area and is performed in one, continuous cycle.

Speed Sawing Technology

Reduce cut times and increase productivity with these saw features: rapid advance blade approach, automatic material sensing, automatic cutting speed transition, feed compensation during the cut, end of cut sensing and automatic retract.

SignoMat Adjustable Character Stamp

SignoMat part stamping is the high speed part marking alternative to carbide scribing. This hard stamping option will hold up to 36 characters, letters or numbers. These characters are stamped to a depth of 1/32” (.8 mm) and at multiple heights of 1/4” (6 mm), 1/2” (12 mm), 5/8” (15 mm) and 3/4” (19 mm). The stamping speed is a swift rate of 1 character per second.

About

Built to keep fabricators ahead of the curve.

We do more than make machines for steel fabricators. We keep you ahead of the fabrication curve through unparalleled partnerships, constant research and development, industry-leading service, cutting-edge technology and quality components to create machines that are built to last. Our customers succeed.